Composite of stone aggregates (quartz, bioquartz, marble, and granite), bound together with unsaturated polyester resin or Biolenic resin. The ideal material for a range of residential and commercial applications, thanks to its exceptional hardness and strength.

Products

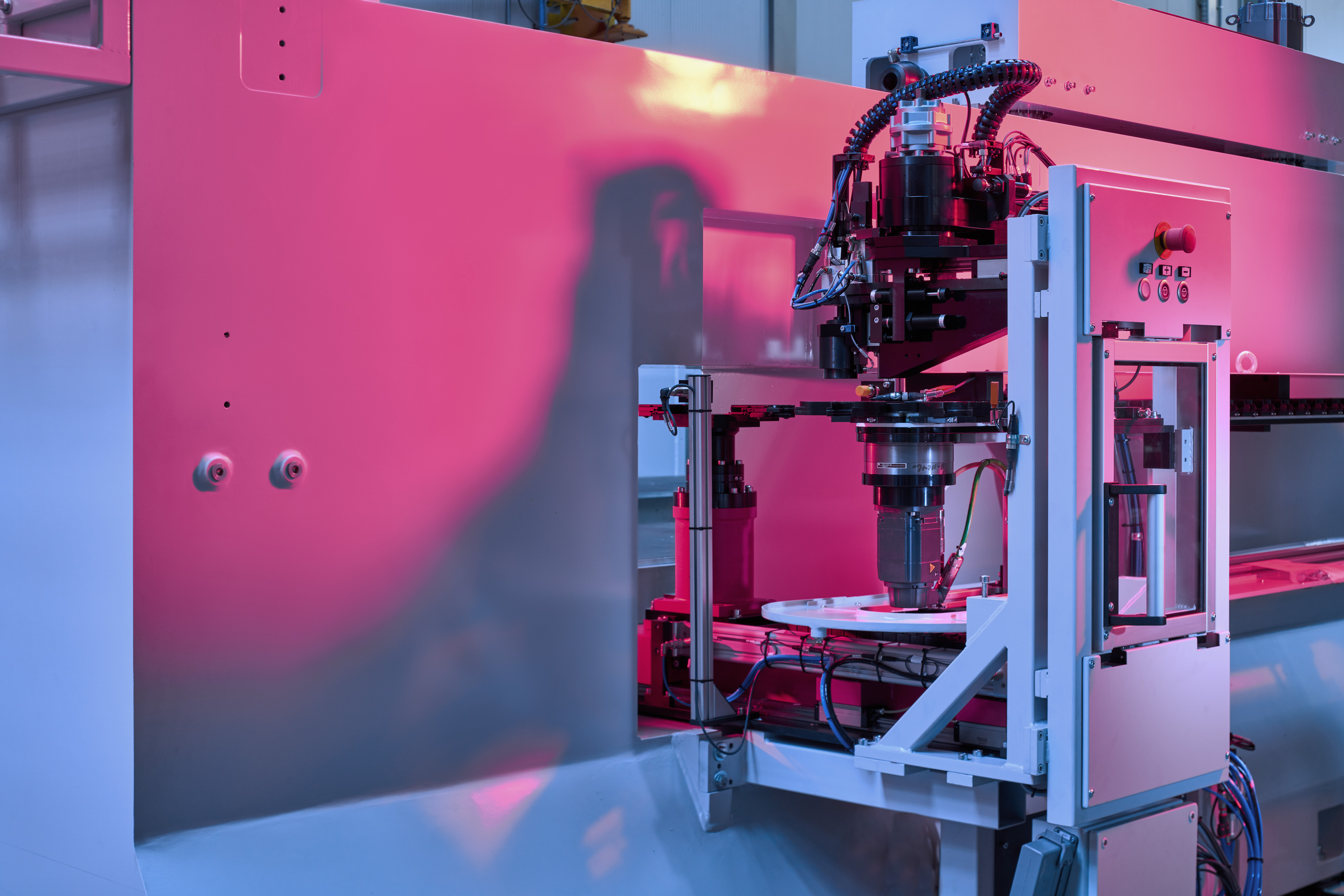

Design and production of advanced machinery, industrial plants, technology and software

Machines and lines

Breton invents, designs and builds specific high tech and high production machining centres, lines and stand-alone machines for processing materials (natural stone, marble, granite, quartz, ceramic, heavy clay, mineral surface, resins and foams, polymers, and metals) and for additive manufacturing.

Plants

Breton supports the quest for excellence in the mineral surface business while pursuing a path of respect for the environment, health, and safety through advanced solutions for low-crystalline silica slab, block, and aggregate production.

These products find application in architecture, interior design, and outdoor applications through excellent technical features and endless design possibilities.

Software

Breton offers software suites and production process management platforms, integrable with legacy systems as necessary, to optimise machine operation and assure full technological control of plants.

Technologies

Breton proposes technological solutions applicable to various sectors to maximise the performance of Breton machines and achieve previously unimaginable levels of precision and production rates.